From Air to Liquid: The Evolution of Data Center Cooling

How Liquid Cooling and Emerging Technologies are Transforming Data Center Efficiency

Table of Contents

Introduction

As the digital landscape rapidly advances, the imperative for more efficient and sustainable data center cooling solutions becomes increasingly paramount. The rise of high-performance computing demands innovations beyond traditional cooling methods. This blog delves into the transformative potential of liquid cooling technologies in data centers, highlighting their role in enhancing energy efficiency and fostering sustainable practices.

Figure 1: Data Center Liquid Cooling Technology Usage Example [1]

Data Center Liquid Cooling Market Size

The global data center liquid cooling market is projected to grow from USD 2.6 billion in 2023 to USD 7.8 billion by 2028, at a CAGR of 24.4% during the forecast period. [2]The market growth is driven by the increasing need for compact and efficient cooling solutions due to the rise of edge computing and Internet of Things (IoT) devices. This type of cooling is particularly beneficial in remote areas and challenging conditions, supporting data handling and cooling of small form factor devices and edge servers.

Figure 2: US data center demand forecast [3]

There are approximately 10,978 data center locations worldwide as of December 2023. [4] As of March 2024, the United States had 5,388 data centers, which is more than any other country in the world. [4] This means around half of the world’s data centers are based in the USA.

The average Data Center consumes as much energy as 25,000 homes. [5] Data centers consumed 7.4 Gigawatts of power in 2023 world wide, a 55% increase from the 4.9 Gigawatts in 2022. [4] In the US, consumption is expected to rise from 200TWh in 2022 to 260TWh in 2026, some six percent of all power use across the country. [6]

Figure 3: Data center electricity usage forecast [3]

The rapid growth in the number of data centers, combined with their high energy consumption, is likely to prompt stricter regulatory compliance requirements to address the urgent energy issues. With cooling systems typically accounting for 40% of energy consumption in a traditional air cooled data center, more efficient data center cooling solutions are becoming increasingly important.

Figure 4: Typical breakdown of energy consumption in air- cooled data centers [7]

Air Cooling vs Liquid Cooling in Data Center

Liquid cooling is a more efficient alternative to air cooling in data centers, particularly due to its ability to handle the higher heat loads generated by modern high-density computing environments. Here are some quantitative insights on the efficiency of liquid cooling compared to air cooling:

Enhanced Energy Efficiency: Liquid cooling systems are significantly more efficient in heat dissipation compared to air cooling. They can absorb and carry away heat up to four times more effectively than air. This efficiency leads to substantial energy savings, with liquid cooling systems potentially reducing energy consumption by up to 90%. [8]

Cooling Capacity: Liquid cooling can handle higher thermal densities effectively. This is crucial as data centers increasingly deploy high-performance computing resources that generate significant heat, which traditional air cooling systems might struggle to manage efficiently. [9]

Increased Rack Density: Modern data centers experience a remarkable increase in rack power densities. A decade ago, average rack densities were around 4-5 kW, but they are now predicted to reach 15-20 kW and even higher in the future. [10] Liquid cooling effectively supports these higher densities, allowing for more compact and efficient data center designs. [8]

Temperature Control and Reliability: Liquid cooling provides superior precision in temperature control, ensuring components operate within optimal temperature ranges. This reduces the risk of overheating and thermal throttling, thereby extending the lifespan of data center equipment and improving overall reliability. [8]

Maintenance and Operational Cost Reduction: Liquid cooling systems generally require less maintenance than air cooling systems. The absence of dust and debris in liquid-cooled environments reduces the risk of component damage, and the closed-loop nature of many liquid cooling systems minimizes the need for frequent maintenance. Additionally, the elimination of extensive air conditioning systems can lead to significant operational cost savings.

Liquid Cooling in Edge Computing and IoT: In edge computing and IoT applications, liquid cooling is becoming increasingly important. Edge computing sites often need to handle high-performance workloads such as data analytics and machine learning, which generate significant heat. Traditional air-cooled solutions may be insufficient in these scenarios, especially in remote or harsh environments where maintaining optimal temperatures is challenging. Liquid cooling, including solutions like direct-to-chip and immersion cooling, provides effective thermal management, ensuring reliability and performance of edge computing nodes

Investment in Quieter Cooling: Liquid cooling is significantly quieter than air cooling because it doesn't rely on large fans, which typically generate more noise. This reduction in noise pollution is critical in dense computational environments like data centers, enhancing the operational environment and reducing auditory stress for maintenance and operational staff.

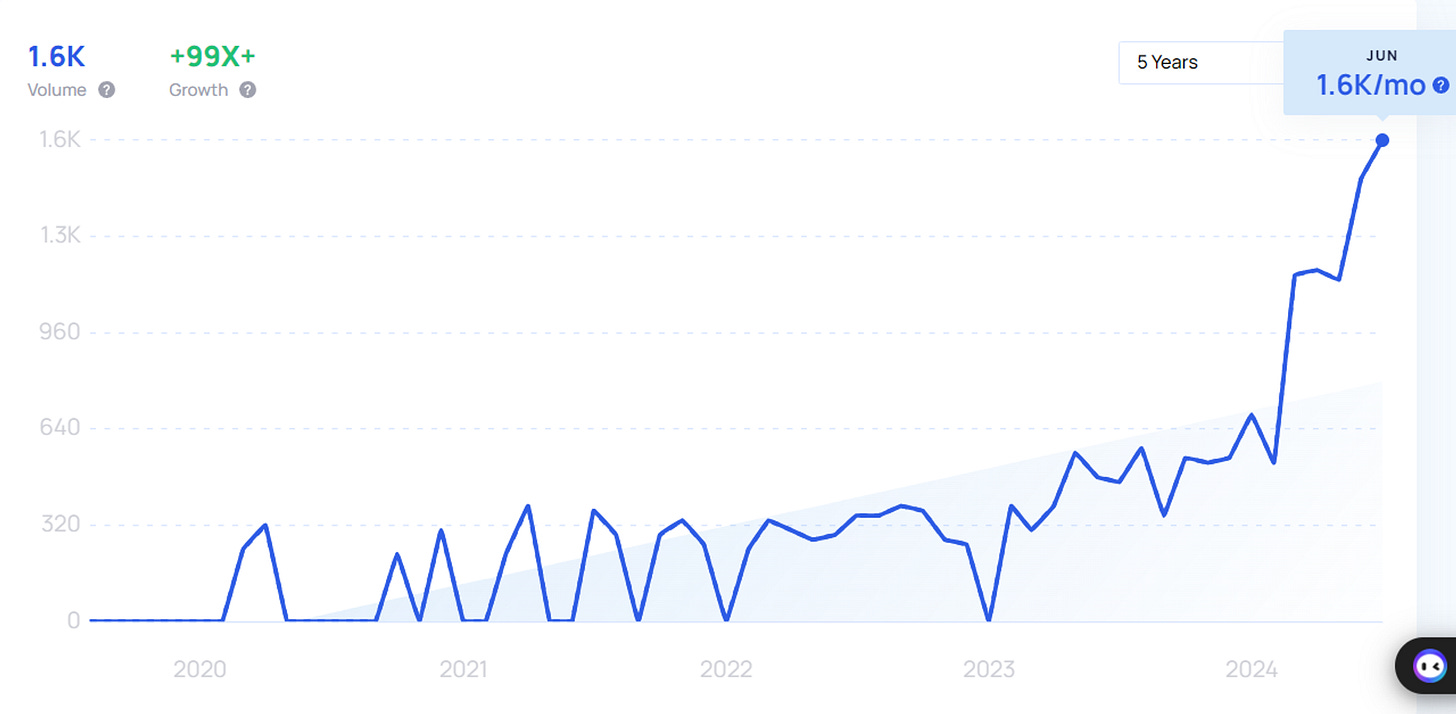

Figure 5: Based on Exploding Topics Liquid Cooling Data Center Trend, this sector is experiencing exploding growth in market sentiment.

Key Considerations in Data Center Cooling Method Selection:

Scalability:

Challenges: Both traditional liquid cooling components like radiator-based and AIO systems face scalability challenges when deployed in large data centers. Managing hundreds or thousands of individual cooling units is less efficient compared to centralized or more integrated cooling solutions.

Solutions: Centralized systems like in-row cooling, chilled water systems, or advanced liquid cooling techniques such as direct-to-chip or immersion cooling are better suited for large-scale deployments. These solutions provide more uniform cooling and are easier to manage and scale.

Efficiency:

Requirements: While air cooling has been the standard due to its relative flexibility and ease of use, it is failing to keep up with the heat output in modern server farms. Prior to the advent of more computation-intensive technologies, most server racks peaked at 20kW. Now, many push or exceed 30kW. Graphics processing units (GPUs), which support AI and machine learning technology, exceed 40kW. Air cooling simply cannot keep up with the heat generated by that level of power use.

Advantages of Liquid Cooling: Advanced liquid cooling solutions, such as direct-to-chip and immersion cooling, offer superior heat dissipation and energy efficiency. These systems can handle higher thermal densities effectively, making them ideal for modern, high-performance data centers.

Figure 6: Liquid Cooling Versus Air Cooling: How Thermal Management Systems Are Evolving [1]

Space and Infrastructure:

Space Constraints: Implementing radiator-based and AIO systems in large-scale data centers requires substantial space for radiators and associated infrastructure. This can potentially reduce the available space for actual computing hardware.

Edge Data Centers: In edge data centers, where space is often limited and environmental conditions can be challenging, liquid cooling provides a compact and efficient solution. Edge data centers benefit from the enhanced cooling efficiency of liquid cooling systems, which can be more easily adapted to smaller, distributed sites.

Integrated Solutions: More integrated cooling solutions like in-row cooling or liquid cooling systems minimize the footprint of cooling infrastructure, optimizing the use of space within the data center.

Figure 7: Edge Data Center Market Size & Trends [11]

Failure Rate:

Reliability: Heat removal is far more consistent and uniform with advanced liquid cooling technology, leading to lower levels of equipment failure and consequent maintenance and replacement. Hotspots in server equipment are a persistent problem and all forms of liquid cooling appear to be superior to air cooling in mitigating or eliminating them. However, chilled water system, immersion cooling and direct to chip method do carry the risk of leakage. Chilled water systems have a higher risk of extensive damage due to potential water leaks affecting multiple components. D2C and immersion cooling systems are better contained and pose less risk of widespread damage. When the fluids are not conductive, leakage typically is not a major threat to IT equipment . But it will cause cooling systems to fail, leading to possible overheating.

Financial Impact: Data center failures can be extremely costly. Over 60% of failures result in at least $100,000 in total losses, the share of outages that cost upwards of $1 million increased is around 15%. [12] Cooling system failures are a significant cause of data center outages, contributing to approximately 14% of all data center failures. [13] Reducing the risk of these failures through more reliable cooling methods can result in substantial financial savings.

Figure 8: Leading causes of data center outages [13]

Repair and Maintenance:

Maintenance: Monitoring and managing cooling liquids in data centers is crucial due to the potential for corrosion, contamination, and other issues that can affect system performance and equipment integrity. Fluids must be regularly tested for contaminants that could hinder heat transfer capabilities, such as increased viscosity from particulate matter. Equipment materials, like metals and sealants, may leach into the fluid, and bacterial growth in water-based systems requires vigilance. Filtration systems have been developed to mitigate these risks, but leaks still need intensive monitoring due to the severe damage they can cause to sensitive components. In two-phase cooling systems, the fluids must be periodically replenished, and securing properly formulated fluids and specific parts can be challenging until demand grows. Moreover, for maintenance efficiency, cold plates and other cooling system components servicing servers must be designed for easy detachment without disrupting the entire system.

Repair: Repair complexities across data center cooling technologies vary: Direct-to-Chip (D2C) involves manageable modular block access; Immersion Cooling demands draining and refilling, but less frequent maintenance; Cold Plate Cooling features easy swaps and leak repairs; Rear Door Heat Exchangers require straightforward access but may involve coolant system components. Air Cooling repairs are typically simpler, focusing on fan replacements and filter cleaning. Chilled Water systems, with their extensive piping and chillers, are the most complex and disruptive to repair.

Digital Art 1: “Liquid Data Flow” illustrates the shift from air to liquid cooling in data centers.

Traditional Liquid Cooling Technologies

Traditional liquid cooling technologies generally encompass methods that use a fluid to transfer heat away from heat-generating components, but do so using simpler, more established techniques compared to advanced systems. Here are some of the commonly recognized traditional liquid cooling methods:

Chilled Water Systems

Prevalence: Very High

Description: These systems use a central chiller to cool water which is then pumped through pipes and coils located near or around the heat-generating elements.

Mechanism: Chilled water absorbs heat from the environment or direct contact with components, then returns to the chiller where it is re-cooled.

Data Center Use: Chilled water systems are among the most traditional and widely used liquid cooling methods in data centers. They use a central chiller to cool water, which is then circulated through cooling coils or air handlers. This technology is especially prevalent in larger and older data centers.

Benefit: Chilled water systems offer high efficiency and capacity, making them suitable for large-scale deployments. They can be integrated into the building's HVAC system, allowing for centralized control and reduced operational costs. The use of water as a coolant is also more effective in absorbing heat compared to air, which enhances the overall cooling efficiency.

Limitations:

Complexity and Cost: Installing a chilled water system involves significant upfront costs and complexity. It requires space for large chillers and a network of piping, which may not be feasible in smaller data centers or retrofit situations.

Maintenance: These systems require regular maintenance of chillers, pumps, and pipes to prevent leaks and ensure efficient operation. Failure to maintain the system properly can lead to inefficiencies or breakdowns, potentially causing downtime.

Flexibility: Once installed, chilled water systems can be less flexible in terms of scaling or reconfiguring compared to more modular cooling solutions. Changes to the data center layout or expansion can require substantial modifications to the piping layout.

Energy Consumption: While chilled water systems are efficient in heat removal, the chillers themselves can be significant consumers of energy, particularly if not optimized for part-load conditions common in dynamically changing IT environments.

Advanced liquid cooling technology

Advanced liquid cooling technologies use specialized designs, materials, and processes to efficiently remove heat from high-performance systems like data centers and power electronics. These technologies enhance heat transfer through direct contact cooling, phase change processes, or improved fluid dynamics, providing precise temperature control to maintain optimal operating conditions. They integrate with equipment design for better space utilization and performance, often using engineered coolants with superior thermal properties and lower electrical conductivity compared to water.

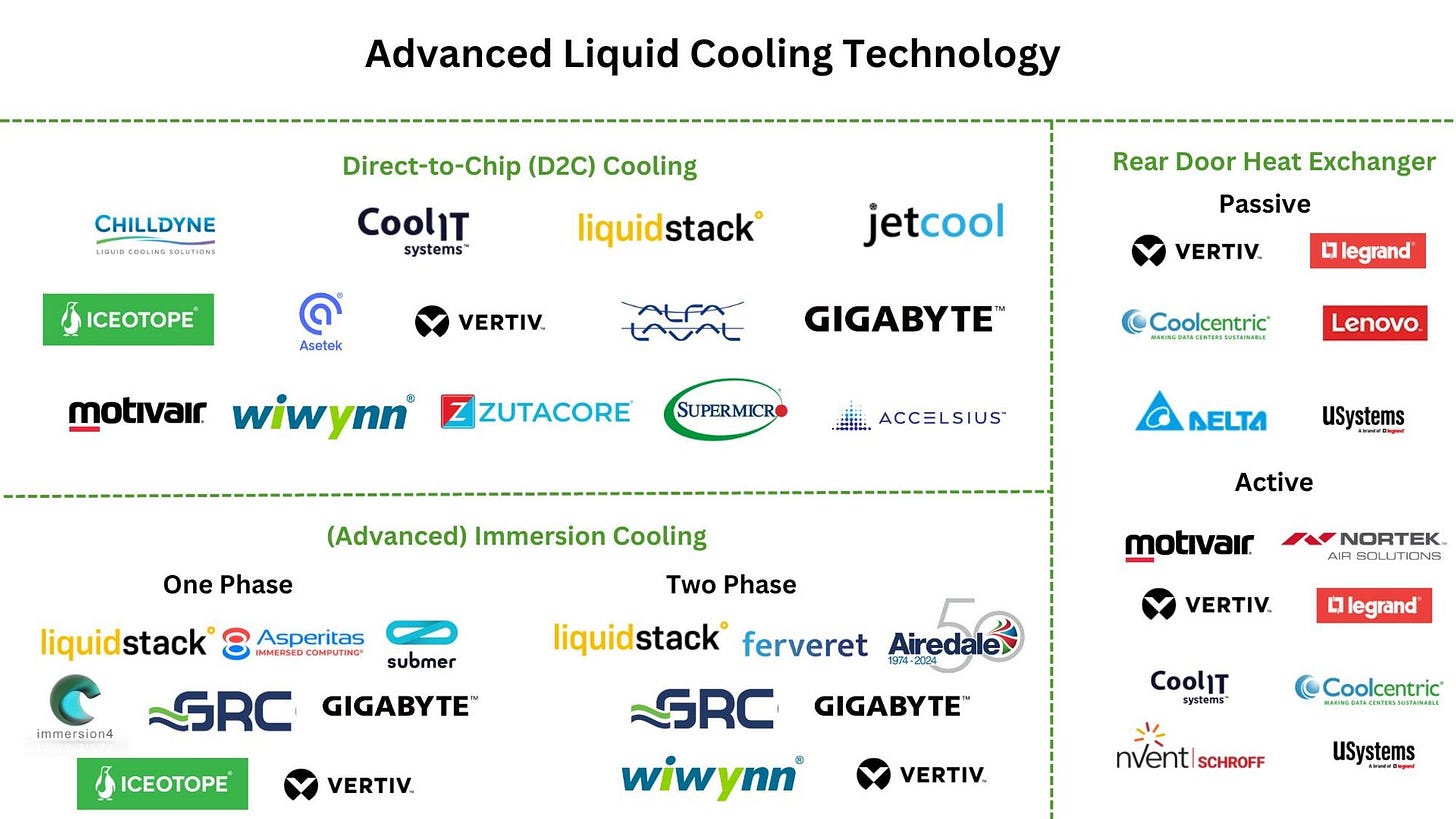

Figure 9: Advanced Liquid Cooling Technology Mapping by Clarice Qiu

Examples of Advanced Liquid Cooling Technologies

Direct-to-Chip (D2C) Cooling

Prevalence: Moderate to High

Description: Direct-to-Chip (D2C) cooling involves attaching cold plates directly to CPUs, GPUs, or other heat-generating components. Coolants, either in single-phase (liquid only) or two-phase (liquid to gas and back), are circulated through these cold plates to absorb and dissipate heat efficiently.

Mechanism: In single-phase systems, the coolant absorbs heat and is recirculated without changing phase. In two-phase systems, the coolant vaporizes at high heat spots and condenses back to liquid in a cooler area of the system.

Data Center Use: Widely adopted in data centers for high-performance computing tasks, particularly where high heat flux management is crucial.

Benefit: Provides precise, efficient cooling directly at the heat source, reducing thermal stress and enhancing performance and longevity of critical components. Two-phase systems, in particular, handle higher heat densities effectively, allowing for closer component packing and smaller cooling infrastructure.

Figure 10: Direct to Chip Cold Plate Cooling, Source: Vertiv

Startup Example: ZutaCore

ZutaCore is a startup specializing in advanced liquid cooling solutions for data centers. The company focuses on direct-on-chip, waterless liquid cooling technology designed to manage heat efficiently and reduce cooling costs in high-density computing environments. With GPUs like the H100 and H200 consuming up to 700W each, ZutaCore's HyperCool® technology effectively dissipates heat directly at the source. This technology cools processors of 1,500 watts or more and handles 100kW per rack, increasing rack-processing density by 300%.

Technology: ZutaCore's technology includes proprietary direct-on-chip cooling solutions that leverage a two-phase, waterless liquid cooling system. This system effectively dissipates heat directly at the source, enhancing cooling efficiency and preventing hotspots.

Product Offering: ZutaCore offers a range of cooling solutions tailored for data centers, including:

HyperCool: Direct-on-chip cooling systems designed for high-density server environments.

HyperCool2: An advanced version with enhanced cooling capabilities and modular design for scalability.

Funding : Around $60M total funding [14]

Immersion Cooling:

Prevalence: Moderate but Growing

Description: Immersion cooling technology involves submerging electronic components or entire systems directly in a non-conductive liquid coolant, eliminating the need for traditional air or direct-contact liquid cooling solutions.

Types:

Single-phase immersion cooling: Components are submerged in a thermally conductive but electrically insulating liquid. The liquid absorbs heat and is circulated through a heat exchanger to dissipate the heat.

Two-phase immersion cooling: Similar to single-phase, but the coolant undergoes a phase change (from liquid to gas) as it absorbs heat, which greatly enhances heat removal. The vapor then condenses back to liquid upon cooling.

Mechanism: Heat is transferred directly from the electronic components to the liquid coolant through conduction and convection. The large contact area and superior thermal properties of the liquid enhance heat dissipation.

Data Center Use: Immersion cooling, involving the submersion of IT hardware in a non-conductive liquid, is gaining traction, especially in sectors that require high-density computing and where space and energy efficiency are critical. This method is still less common but is seeing increased interest due to its high efficiency and potential cost savings in operation.

Benefit: Significantly reduces cooling energy consumption and allows for more compact system designs. It also minimizes noise and dust issues, enhancing system longevity and reliability.

Figure 11: Immersion Cooling, Source: Vertiv

Startup Example: Asperitas

Asperitas specializes in immersion cooling solutions that leverage their proprietary Immersed Computing® technology. This technology is centered around enhancing data center sustainability and operational efficiency by immersing server hardware in dielectric liquids, which efficiently transfer heat without the need for traditional air cooling methods.

Technology:

Immersed Computing®: Asperitas has developed this cutting-edge technology based on single-phase immersion cooling. It utilizes natural convection to circulate the cooling fluid, eliminating the need for mechanical pumps in many configurations and thereby reducing energy consumption.

Natural Convection Driven Circulation: This innovative approach minimizes moving parts within the cooling system, enhancing reliability and further reducing energy costs associated with cooling.

Product Offering:

AIC24 Module: A self-contained immersion cooling system that supports high-density compute environments. It's designed to be easily integrated into existing IT infrastructure.

Modular Immersion Cooling Systems: These systems are scalable and can be adapted to different server types and configurations, providing flexibility for data center operators.

Heat Reuse Applications: Asperitas also focuses on the potential for heat reuse from their systems, offering solutions that can redirect waste heat for other applications, enhancing overall energy efficiency.

Funding: Founded in 2014, Asperitas has raised $2.15M based on Pitchbook

Learn more Asperitas Immersion Cooling:

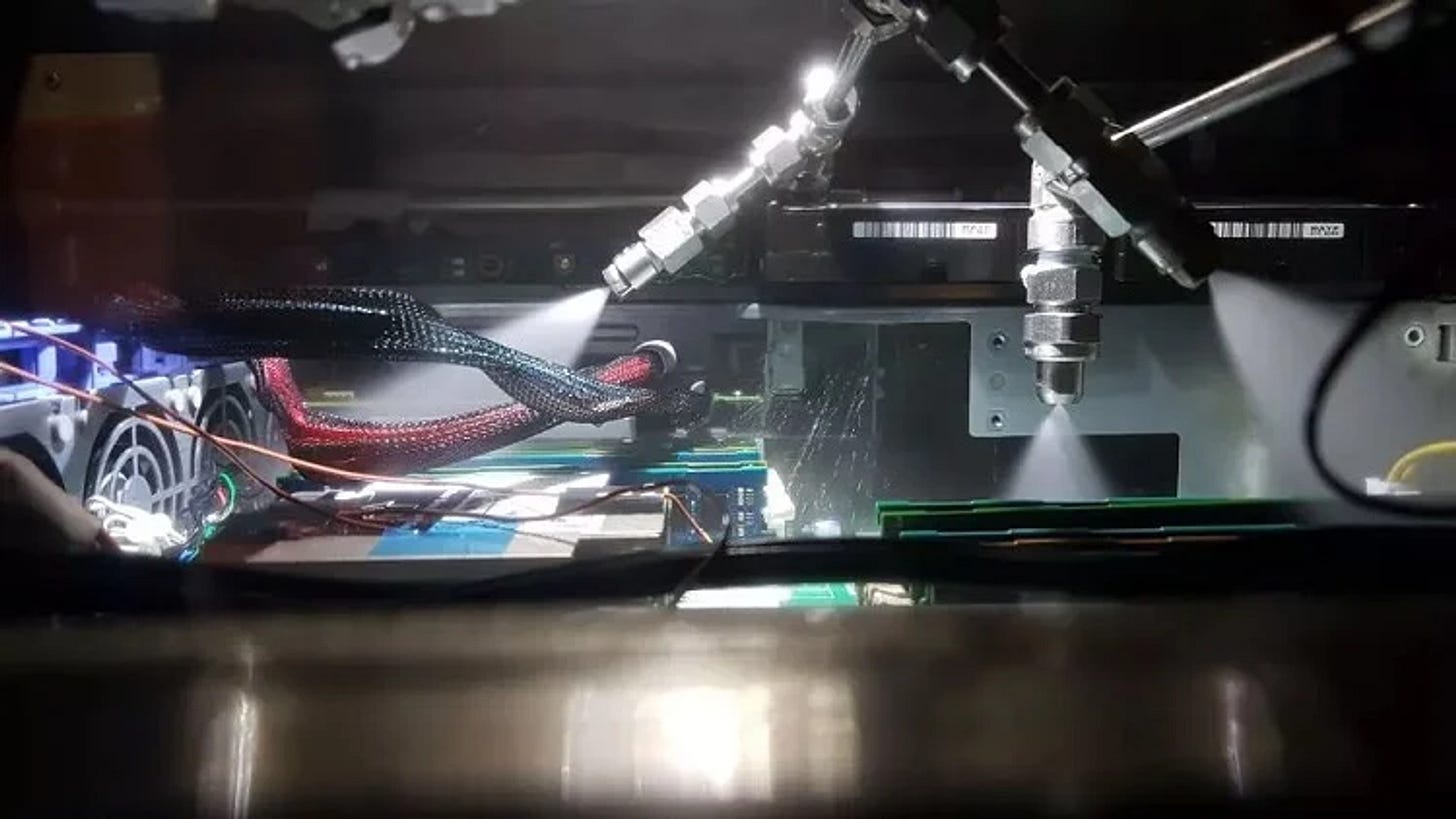

Spray Cooling

Prevalence: Moderate

Description: Spray cooling technology involves directing a fine mist of coolant directly onto hot surfaces within electronic devices.

Mechanism: The sprayed coolant evaporates upon contact with the hot surfaces, absorbing heat rapidly through phase change, then the vapor is condensed and recirculated.

Data Center Use: Ideal for high heat flux components like CPUs and GPUs in densely packed server environments.

Benefit: Offers superior cooling performance by enabling higher heat dissipation rates, allowing for tighter component packing without thermal throttling.

Company Example: AIRSYS

AIRSYS North America is a leading provider of cooling solutions tailored for data centers, telecommunications, and educational facilities. Their technology portfolio includes advanced systems like LiquidRack, which utilizes spray cooling, along with other efficient liquid and air cooling methods. These technologies feature energy recovery and diagnostic monitoring to optimize performance.

Product Offering: AIRSYS offers specialized products like the UniCool-Edge™ for edge data centers and stackable CRAC units, designed to enhance cooling efficiency and system reliability.

Use Cases: AIRSYS solutions are essential in environments requiring precise temperature control such as data centers, where they manage heat to ensure operational continuity and telecom infrastructures to maintain system integrity under various conditions.

Subcooled Boiling:

Prevalence: Low but Growing

Description: Subcooled boiling involves boiling a coolant at temperatures below its standard boiling point under atmospheric pressure. This is achieved by increasing the system's pressure, which allows the coolant to absorb more heat before it begins to boil. As the liquid coolant passes over hot components, it partially vaporizes at these subcooled temperatures. The latent heat of vaporization helps remove heat more efficiently than typical single-phase liquid cooling.

Mechanism: The coolant circulates through cooling blocks attached to heat-generating components like CPUs. When it absorbs enough heat, part of the coolant undergoes a phase change to vapor, despite being below the typical boiling point at atmospheric pressure. The mixture of liquid and vapor then moves to a condenser where the vapor condenses back into a liquid, releasing the heat.

Data Center Use: Ideal for applications requiring high cooling capacities without raising the coolant's temperature significantly. Subcooled boiling can handle extreme heat loads typical in advanced computing applications like artificial intelligence and big data analytics. While still emerging, its usage could expand as the demand for more efficient thermal management solutions increases in the face of escalating power densities in modern IT equipment.

Benefits: Enables more efficient heat removal compared to single-phase liquid cooling, handling higher heat densities without significant increases in temperature.

Startup Example : Ferveret

Ferveret is a forward-thinking company dedicated to revolutionizing liquid cooling technology, particularly for data centers and high-performance computing applications. They are recognized for innovative solutions that significantly reduce carbon emissions and energy costs associated with traditional cooling methods. Ferveret's technology boasts 96% less energy wasted, a 40% smaller footprint, and approximately 2X improvement in CPU and GPU performance, making their solutions highly efficient and sustainable for modern computing needs.

Technology: Ferveret employs subcooled boiling technology and two phase immersion cooling solution in their liquid cooling systems. This advanced method is capable of removing high heat fluxes efficiently from processors and other heat-generating components. By enabling the coolant to absorb a substantial amount of heat before it begins to boil, Ferveret's technology enhances the thermal management of critical infrastructure without the excessive energy typically consumed by conventional cooling methods.

Product Offering: Ferveret's primary products revolve around their specialized liquid cooling systems that utilize their patented subcooled boiling technology. These systems are designed to be highly efficient, reducing both the physical footprint of cooling infrastructure and the associated energy consumption. This makes them particularly suited for environments where space and energy usage are critical considerations.

Funding: Founded in 2021, $2.2 M total raised based on Cruchbase

These advanced technologies are often more complex and costly than traditional air or simple liquid cooling systems. However, they provide significant advantages in scenarios where high-density heat needs to be managed efficiently, such as in cutting-edge data centers, high-performance computing, and sophisticated industrial applications. The choice of technology typically depends on the specific heat management needs, cost considerations, and potential return on investment through energy savings and improved system reliability and longevity.

Emerging Liquid Cooling Technologies

Advanced Immersion Cooling Systems

Prevalence: Moderate and Increasing

Description: Enhanced immersion cooling with engineered fluids, often incorporating nanoparticles to improve thermal conductivity and heat capacity.

Mechanism: Submerging components in advanced dielectric fluids with improved heat transfer properties.

Use Case: Next-generation data centers, high-performance computing, and blockchain mining operations.

Benefit: Increased cooling efficiency, reduced energy consumption, and higher component densities.

Startup Example: Liquid Stack

LiquidStack specializes in advanced liquid cooling solutions, focusing on two-phase immersion cooling technology. This method enhances data center efficiency by submerging compute equipment in a dielectric liquid, which boils to capture heat and then condenses to release it, significantly reducing space requirements and energy consumption. It cuts mechanical equipment energy use by 40%, CAPEX by 33%, TCO by 32%, and compacts data center white space by 69%. Additionally, it can save over 300 billion liters of water annually and repurpose heat for other applications.

Technology: The company's flagship technology includes two-phase immersion cooling, which offers superior thermal management by utilizing a passive cooling cycle. This involves the liquid coolant boiling as it absorbs heat from the servers, then condensing and releasing the heat outside the system.

Product Offering: LiquidStack's product range includes:

DataTank™ Series: Modular immersion cooling tanks designed for various scale deployments, providing up to 252kW cooling capacity per rack.

MicroModular™ and MacroModular™ Systems: These are prefabricated solutions that provide up to 1.5MW of cooling in modular formats, suitable for different operational scales.

Funding : Founded in 2012, Series B with $10M total funding amount

Advanced Dielectric Fluid Cooling

Prevalence: Moderate and Growing

Description: Enhanced dielectric fluids with better thermal properties for cooling sensitive electronic components.

Mechanism: Circulating advanced dielectric fluids around or immersing components to absorb and dissipate heat.

Use Case: High-voltage transformers, power electronics, and data center servers.

Benefit: Safe for electronic equipment, high levels of heat dissipation, enabling more compact designs and lower operational costs.

Company Example: Engineered Fluid

Engineered Fluids offers a range of engineered dielectric coolants designed specifically for the challenges of thermal management in electronics and electrical systems. Their focus is on creating products that are safe, effective, and environmentally friendly, supporting industries where heat management is crucial.

Technology:

Single-Phase Liquid Immersion Cooling: This core technology involves submerging electronic components or entire devices in a dielectric liquid that efficiently absorbs and dissipates heat without the need for mechanical cooling components.

Dielectric Fluids: Engineered Fluids develops and supplies specialized fluids that offer excellent thermal conductivity and electrical insulation, ensuring safe and efficient operation of immersed components.

Product Offering:

ElectroCool®: A series of dielectric coolants that provide effective full immersion cooling for electronics such as servers, GPUs, and other semiconductors.

AmpCool®: Specially formulated for cooling batteries, electric motors, and electronic motor controllers, offering enhanced cooling, insulation, and lubrication.

SubmergeDeep®: Designed for high-pressure and high-heat environments, ideal for subsea and other challenging applications.

Chip Embedded Cooling

Prevalence: Low but Emerging

Description: Chip Embedded Cooling involves the integration of cooling channels directly into the chip or the substrate on which electronic components are mounted. This innovative cooling technology embeds microfluidic channels within or directly adjacent to the chip to facilitate the direct removal of heat from hot spots, significantly enhancing the efficiency of thermal management.

Mechanism: The mechanism behind Chip Embedded Cooling relies on the circulation of a coolant fluid through microchannels that are fabricated as part of the chip or the supporting substrate. These microchannels allow the coolant to come into close proximity with high heat-generating areas, effectively absorbing heat directly at its source. As the coolant absorbs heat, it is circulated out of the chip to a heat exchanger where it is cooled before being recirculated.

Use Case: Chip Embedded Cooling is ideally suited for high-performance computing environments, such as data centers, where maintaining optimal operating temperatures is crucial for reliability and efficiency. This technology is particularly beneficial for densely packed servers and GPUs that handle complex computations and large data workloads. It also finds applications in embedded systems within aerospace and automotive industries, where effective thermal management is critical to prevent system failures due to overheating.

Benefit: The primary benefit of Chip Embedded Cooling is its superior cooling efficiency, which allows electronic components to perform at high operational frequencies without the risk of thermal throttling. This efficiency not only extends the lifespan of components but also reduces the physical space required for cooling infrastructure, leading to more compact system designs. Additionally, this method significantly lowers energy consumption associated with cooling, which can lead to considerable cost savings, especially in energy-intensive environments like data centers.

Complementary Cooling Technologies:

These technologies complement the primary advanced and emerging cooling solutions, enhancing overall efficiency and addressing specific cooling needs in data centers.

Radiator-Based Cooling in Data Centers

Prevalence: Moderate to High

Description: Radiator-based cooling systems use a radiator to dissipate heat absorbed by the coolant circulating through the system. Coolant, often water or a glycol mixture, absorbs heat from components and then passes through a radiator where fans expel the heat into the surrounding air.

Mechanism: The coolant captures heat from components like CPUs or GPUs, and is pumped to a radiator. At the radiator, air is forced through the radiator's fins by fans, transferring the heat from the coolant to the air.

Use Case: Commonly used in both automotive and computer systems, especially in personal computers and smaller server setups where moderate cooling is sufficient.

Benefit: Provides a straightforward and effective way to manage heat, with components that are readily available and easy to replace or upgrade. It is relatively simple to install and maintain, making it popular for a wide range of applications.

Data Center Use: Radiator-based cooling systems are quite common in data centers, especially in those configurations where water or liquid cooling solutions are implemented. They typically involve the use of radiators to dissipate heat from the coolant that absorbs heat from the data center equipment. This method is often used as part of a larger cooling infrastructure that might include chillers, cooling towers, and other heat exchange mechanisms.

Limitations: In traditional large data centers, using individual radiators for each server could be inefficient due to space constraints and the complexity of managing multiple cooling units. This method is also less efficient in environments where high-density cooling is required due to its reliance on ambient air.

Closed-Loop (AIO) Coolers in Data Centers

Prevalence: Low

Description: Closed-loop or All-in-One (AIO) coolers are pre-assembled, maintenance-free systems that consist of a pre-filled coolant loop, a radiator, a pump, and a fan. These systems are sealed and do not require refilling or maintenance under normal conditions.

Mechanism: The integrated pump circulates coolant through a cold plate attached to the heat source (like a CPU), then to a radiator where heat is released via fans. The closed loop operates independently without interaction with other system components.

Use Case: Widely used in consumer PCs and gaming rigs where users require better cooling efficiency than air coolers and a cleaner, more aesthetic setup without the complexity and maintenance of custom water cooling.

Benefit: Offers enhanced cooling performance compared to standard air coolers and is easier to install and maintain than open-loop water cooling systems. AIO coolers provide a balance of performance and convenience, making them a popular choice for users who are not ready to commit to custom water cooling setups.

Data Center Use: Closed-Loop Coolers, also known as All-In-One liquid coolers, are less common in traditional data center environments. These are more frequently found in personal computing and gaming systems where they are used for CPU or GPU cooling. In data centers, the scale and the custom requirements often necessitate more robust and adaptable cooling solutions than what typical AIO systems can provide. However, they might be used in specific high-performance computing applications or in small scale or specialized data centers where standardization and ease of maintenance are priorities.

Limitations: The use of AIO coolers in a standard data center environment is generally limited due to scalability issues. Each unit is self-contained, which might simplify maintenance but can also lead to increased operational complexities and costs when scaling up. Moreover, the dependency on air flow through radiators can be a drawback in tightly packed data centers.

Rear Door Heat Exchanger

Prevalence: Moderate

Description: A rear door heat exchanger is an attachment to the back of server racks that acts as a passive or active cooling device. As hot air exits the servers, it passes through this heat exchanger before re-entering the data center.

Mechanism: The hot air generated by the servers is funneled through a heat exchanger integrated into the rear door of the server cabinet. Coolant flowing through the heat exchanger absorbs the heat from the air, significantly lowering its temperature before it is released back into the room.

Active Rear Door Heat Exchangers:

Description: Utilize fans or other mechanical means to actively draw air through the heat exchanger, improving airflow and heat dissipation.

Passive Rear Door Heat Exchangers:

Description: Rely on natural convection and the existing airflow generated by the server equipment to passively cool the air.

Data Center Use: This technology is frequently used as an augmentation to existing cooling architectures, particularly in data centers looking to improve cooling efficiencies without a complete overhaul.

Benefit: Enhances overall cooling efficiency, helps maintain ambient temperature within the data center, and reduces the workload on central cooling systems, leading to energy savings.

Figure 12: Rear- Door Heat Exchanger, Source: Vertiv

Company Example: Motivair

Motivair Corporation excels in delivering advanced cooling solutions tailored for digital infrastructures and high-performance computing (HPC). The company is known for its cutting-edge technologies and products that address critical cooling needs across various sectors, ensuring operational efficiency and reliability.

Technology: Motivair utilizes several innovative cooling technologies:

Direct Liquid Cooling (DLC): This technology focuses on direct heat removal from chips, improving thermal management for high-density computing.

Free-Cooling Chillers: These chillers leverage external ambient temperatures to reduce the reliance on mechanical cooling, enhancing energy efficiency.

ChilledDoor® Rack Cooling System: A sophisticated active rear door heat exchanger that efficiently captures and removes waste heat directly from server racks, significantly improving the effectiveness of cooling in data centers.

Product Offering: Motivair's comprehensive product lineup includes:

Coolant Distribution Units (CDUs): These are central to ensuring the precise management and circulation of coolant within cooling systems.

Dynamic® Cold Plates: Tailored solutions for cooling high-heat generating components like CPUs and GPUs.

Scroll and Free-Cooling Chillers: High-efficiency chillers that offer optional free-cooling capabilities to optimize energy usage.

In-Rack Manifolds and HDUs (Heat Dissipation Units): Essential for distributing coolant effectively within racks.

Coolant Distribution Units (CDUs)

Prevalence: Moderate to High

Description: CDUs are specialized devices that manage the delivery, pressure, temperature, and purity of coolant in a liquid cooling system.

Mechanism: They function as the central point of control for liquid cooling systems, ensuring that coolant is delivered at the optimal temperature and flow rate to various parts of the system, then returning it for reconditioning.

Data Center Use: CDUs are quite prevalent in modern data centers, especially those utilizing liquid cooling solutions to manage higher heat loads efficiently. CDUs play a crucial role in these setups by maintaining the pressure, temperature, and flow of the coolant to optimize the cooling system's performance. They are particularly important in facilities that use chilled water systems or direct-to-chip cooling, as they ensure that the coolant is delivered effectively across complex infrastructures.

Benefit: Enhances the efficiency and reliability of the cooling system by maintaining consistent coolant characteristics, improving system performance and longevity.

Company Example: Vertiv

Vertiv excels in delivering high-performance liquid cooling solutions tailored for the rigorous demands of data centers and high-performance computing environments. Their sophisticated liquid cooling line is designed to address the increasing heat densities and energy efficiency requirements in modern IT infrastructures.

Technology: Vertiv's liquid cooling technologies encompass:

Coolant Distribution Units (CDUs): Such as the Vertiv™ XDU 1350 and XDU 450, which are central to the efficient operation of their cooling systems, providing precise control over coolant flow, temperature, and pressure.

Direct Liquid Cooling: This technology focuses on removing heat directly at the source — CPUs, GPUs, and other critical components — enhancing system efficiency and component performance.

ChilledDoor® Systems: These are rear door heat exchange solutions that attach to server racks to remove heat directly from the exhaust air, maximizing cooling efficiency and minimizing the data center footprint.

In-Row Cooling: Designed to be placed directly in line with server racks, Vertiv’s in-row cooling units provide localized, targeted cooling to hot spots within the data center, improving the overall effectiveness of temperature management.

Product Offering: Vertiv's liquid cooling product offerings include:

Rack-Based Cooling Solutions: Integrating CDUs, ChilledDoor® systems, in-row cooling, and other liquid cooling components designed to fit seamlessly into existing data center configurations.

Customizable Coolant Pathways: Solutions tailored to meet the specific needs of high-density computing environments, including bespoke pipework and manifold systems that ensure optimal cooling distribution.

Advanced Control Systems: These systems monitor and manage the performance of liquid cooling solutions, ensuring they operate at peak efficiency and adapt to varying load requirements.

In-Row Cooling

Prevalence: Moderate

Description: In-Row Cooling units are placed directly in line with server racks. These specialized cooling units integrate seamlessly with the rows of server cabinets, providing localized cooling to hot spots within the data center.

Mechanism: These units draw in hot air from the server aisle, cool it using internal heat exchangers and chilled water or refrigerant, and then expel the cooled air back into the aisle, close to the server intakes. This proximity minimizes the mixing of hot and cold air, improving cooling effectiveness.

Data Center Use: In-row cooling solutions are commonly used in data centers where high-density configurations create significant localized heat that needs to be managed directly at the source. It’s particularly effective in contained aisles where hot and cold aisle setups are used to maximize efficiency. In-row cooling units can be added or reconfigured based on changing demand, making them a versatile choice for growing or fluctuating data center needs.

Benefit: Targets cooling precisely where it's needed, reducing energy consumption by minimizing the distance cooled air travels and improving the efficiency of heat removal from critical areas.

Future Trend of Data Center Cooling

The future outlook for data center cooling technologies is expected to significantly evolve towards more sustainable and efficient methods. Looking forward, several innovative trends are likely to shape cooling strategies:

Liquid Cooling: Liquid cooling and immersion cooling are likely to become more prevalent, driven by their superior efficiency in heat management and potential for energy savings. These technologies also align with increasing regulatory pressures to reduce carbon footprints and energy consumption.

Modular Cooling: As data centers grow and fluctuate in computational demand, modular cooling solutions provide flexibility, allowing cooling capacity to be scaled up or down as needed without extensive infrastructure changes.

AI-Driven Cooling: Artificial intelligence will increasingly automate cooling systems, optimizing energy use and adapting to changing conditions in real-time, reducing costs and improving efficiency.

Heat Recycling: There's a growing trend in using the waste heat from data centers for district heating, agricultural applications, or other industrial processes, turning a byproduct into a valuable resource.

Renewable Energy Integration: Cooling systems that integrate with renewable energy sources like solar or wind power reduce reliance on non-renewable energy and decrease carbon emissions.

Hybrid Cooling Systems: Combining air and liquid cooling solutions can offer more efficient cooling tailored to specific server loads and environmental conditions, enhancing overall energy efficiency.

Digital Art 2: “Vapor Flow” captures the essence of two-phase immersion cooling, with servers submerged in liquid and vapor rising gracefully.

Reference:

[1] Understanding Liquid Cooling Options and Performance:

https://www.vertiv.com/en-asia/solutions/learn-about/liquid-cooling-options-for-data-centers/

[2] Data Center Liquid Cooling Market: https://www.marketsandmarkets.com/Market-Reports/data-center-liquid-cooling-market-84374345.html

[3] Analyzing Energy Consumption: Unleashing the Power of Data in the Energy Industry https://www.datadynamicsinc.com/blog-analyzing-energy-consumption-unleashing-the-power-of-data-in-the-energy-industry/

[4] 115 Data Center Stats You Should Know In 2024 https://brightlio.com/data-center-stats/#:~:text=Global Data Center Statistics,worldwide as of December 2023.

[5] 8 Data Center facts you might not know https://www.cirkla.tech/single/385

[6] Global data center electricity use to double by 2026 - IEA report https://www.datacenterdynamics.com/en/news/global-data-center-electricity-use-to-double-by-2026-report/#:~:text=In the US%2C which the,power use across the country.

[7] Optimizing energy consumption for data centers https://www.sciencedirect.com/science/article/abs/pii/S1364032115016664

[8] How Power Density is Changing in Data Centers and What It Means for Liquid Cooling https://jetcool.com/post/how-power-density-is-changing-in-data-centers/

[9] Examining Data Center Liquid Cooling: Immersion vs. Direct-to-Chip Systems https://blog.enconnex.com/data-center-liquid-cooling-immersion-direct-to-chip-more

[10] Data Center Liquid Cooling 101: https://www.sunbirddcim.com/blog/data-center-liquid-cooling-101

[11] Edge Data Center Market Size & Trends https://www.grandviewresearch.com/industry-analysis/edge-data-center-market-report

[12] Uptime Institute’s 2022 Outage Analysis Finds Downtime Costs and Consequences Worsening as Industry Efforts to Curb Outage Frequency Fall Short https://uptimeinstitute.com/about-ui/press-releases/2022-outage-analysis-finds-downtime-costs-and-consequences-worsening

[13] Uptime: Longer Data Center Outages Are Becoming More Common https://www.datacenterfrontier.com/cloud/article/11427329/uptime-longer-data-center-outages-are-becoming-more-common

[14] Three kilometers from Gaza: Israeli startup poised to lead AI chip cooling revolution https://www.calcalistech.com/ctechnews/article/3dmkm9a53

Thank you for this in-depth article! Great job!